In many technological processes, materials and products in the form of liquid, suspension, gel, cream or paste must be heated continuously without storage in the tank. The chemical and food industries use it most often.

Unlike other heating methods, where heat is not transported by conduction or convection, microwaves penetrate deeper layers of liquid and semi-liquid materials and products. So they are heated evenly throughout their entire volume.

An additional advantage of this technology is the lack of physical contact between the heat source and the heated product. This is important when we want to maintain sterility or we are dealing with chemically aggressive materials.

ISA CHEM1710 flow reactor

The ISA CHEM1710 reactor with 4.5 kW microwave power is used for intensive heating of liquids flowing through the coil through two microwave chambers.

The gases formed in the chemical process are discharged from the coil through the culverts to the coolers.

The internal reactor systems are cooled with water.

Due to the small size and high performance, it is used in laboratories, as a test device or in a small technological process.

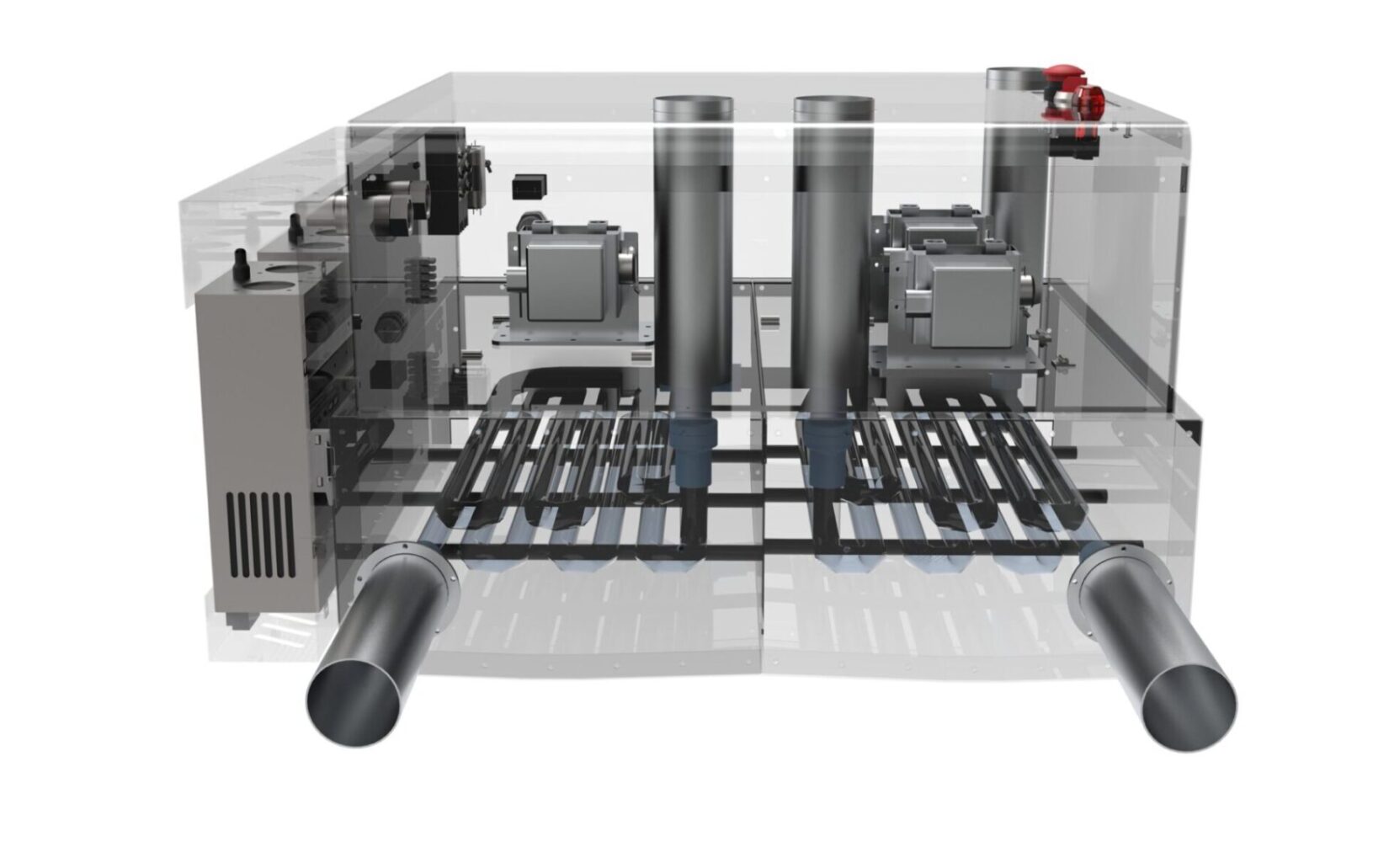

Flow reactor 224 kW

The 224 kW flow reactor design will be one of the largest microwave devices of this type in Poland.

Its task will be to heat chemically aggressive fluid to a temperature of about 130 oC.

We estimate that the entire construction will take about 40 m3.