Ta strona dostępna jest również w polskiej wersji językowej

Ta strona dostępna jest również w polskiej wersji językowej

Microwaves are revolutionizing industrial chemistry — according to some very optimistic estimates, they can accelerate chemical reactions many times over while also increasing their efficiency. Even in early studies, key benefits of this technology were observed: shorter reaction times, higher yields, and rapid heating (up to 10°C/s) in ionic liquids.

With technological advancements, modern industrial microwave systems now offer precise control of reaction parameters and improved energy efficiency. As a result, they are increasingly being adopted as a viable alternative.

Examples of the use of microwaves in the chemical industry can be found on the website Projects

The Effect of Microwaves on Chemical Reactions

Microwave heating utilizes the internal structure of dielectric materials to generate heat. Three key parameters play a crucial role: dielectric constant (ε’), dielectric loss factor (ε’’), and the loss tangent (tan δ). Unlike conventional heating, microwaves heat substances with high loss factors (e.g., polar solvents) more effectively. This enables precise control of reactions even in multiphase mixtures.

In industrial systems (operating at 2.45 GHz), microwave energy is too low to break chemical bonds, but it is sufficient to induce dipole vibrations (e.g., water molecules) and ion polarization in liquids and solutions. The resulting molecular friction is converted into heat.

Microwave Devices in the Chemical Industry

The general term "Chemical Reactors" refers to all types of equipment used in chemical processes. For clarity, we will continue using this designation.

In modern chemistry, two main types of microwave reactors are used, distinguished by the dimensions of the reaction chamber:

- Monomode systems – when the chamber dimensions do not exceed half the wavelength.

- Multimode systems – chambers larger than half the wavelength, in which waves are dispersed throughout a larger volume.

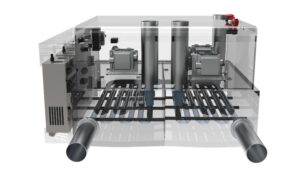

Continuous-Flow Reactor

In this type of device, the process fluid flows continuously through the microwave chamber. It can be transferred through a simple straight tube, a coil, a tightly wound spiral, or an overflow tank. The flow may be gravity-fed or forced using a pump system. Key advantages include process scalability, improved control of reaction parameters, and suitability for integration into production lines.

Batch-Loop Reactor

This reactor is used in processes that require cyclic heating of substrates — for example, during the esterification of (S)-pyroglutamate. The main benefits include easy transition from laboratory to industrial scale and the ability to perform parallel reactions. A practical setup may consist of a diaphragm pump, tubular reactor, and a microwave furnace.

Examples of Microwave Assisted Reactions

- Transesterification: Ethyl caprylate + (R,S)-1-phenylethanol; Vinyl acetate + (R,S)-1-phenylethanol

- Esterification: Adipic acid + n-butanol/n-octanol

- Synthesis of cyclic compounds: Aniline + 1,5-dibromopentane; 3-Chloroaniline + bis(2-chloroethyl)amine·HCl

- Oxidation: Benzyl alcohol → benzaldehyde

- Ether synthesis: Methyl 3,4,5-tridodecyloxybenzoate + dodecyl bromide

- Laurydon process: (R,S)-pyroglutamate + n-decanol

Microwave-assisted chemical reactions are an effective method for scaling up industrial processes. Key advantages include rapid heating of reaction mixtures along with precise control of process parameters. This technology offers significantly higher efficiency compared to conventional methods — for certain heterogeneous reactions, acceleration by up to a factor of 9 has been observed.