Ta strona dostępna jest również w polskiej wersji językowej

A magnetron microwave head is used in industrial systems, microwave reactors, technological lines, chambers and tunnels. The possibility of selecting technical parameters, dimensions and shapes provides the designer with freedom to plan appropriate solutions applied in the food industry, chemical industry and the research sector.

The magnetron switching power supply is selected according to the specific system configuration and operating mode. In microwave dryers, it should provide stable power delivery with the possibility of microwave power control. In plasma systems or laboratories, low-ripple output voltages may additionally be required.

A device or system for measuring microwave leakage is taken into account in order to meet basic occupational health and safety requirements. The designer and the user may select either a handheld instrument or stationary sensors connected to the technological line management system.

Examples of completed orders can be found on the website Projects

Microwave Magnetron Heads

Devices, systems, and production lines utilizing microwaves require at least one source of microwave radiation. In industrial applications, MMH series magnetron heads manufactured in Poland by MARKOM are used.

Devices, systems, and production lines utilizing microwaves require at least one source of microwave radiation. In industrial applications, MMH series magnetron heads manufactured in Poland by MARKOM are used.

Practical Examples of Magnetron Head Applications

Magnetron microwave heads produced by MARKOM Microwaves operate, among others, in: production lines (drying, heating), chemical industry (process enhancement), food processing (thermal treatment, puffing), research departments (hardening of foundry cores), and scientific institutions (liquid heating).

Design and Technical Specifications

The MMH magnetron heads are compatible with various microwave systems, both in research and industrial applications. They feature a compact design and low weight. All circuits – microwave, power supply, and control – are housed within a single enclosure. Aluminum alloy shields can be anodized or powder-coated, providing corrosion resistance. An efficient cooling system ensures effective heat dissipation.

The microwave output, finished with a mounting flange, complies with one of the international standards – WR340 or WR430. This allows integration of our microwave heads with components from different manufacturers.

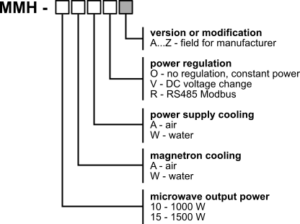

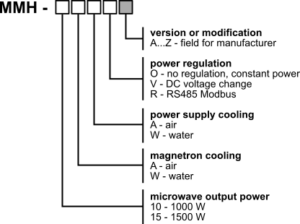

Available Microwave Head Variants

The device can operate at an output power of 1000 W or 1500 W, depending on application needs. It offers three cooling system variants: air-cooled, water-cooled, and hybrid – where the power supply is air-cooled and the magnetron is water-cooled. Two operating modes are supported: constant output power or continuous power regulation. Control is possible in two ways: via control voltage adjustment or through an RS485 interface with Modbus RTU protocol. Thanks to the Modbus RTU implementation, integration with SCADA systems and remote monitoring of operating parameters are possible.

Support and Service

MARKOM provides full technical support for MMH magnetron heads, maintaining its own service and warehouse facilities in Poland. Each magnetron head controlled via RS485 comes with a complete Modbus protocol description. MMH heads are configured prior to shipment – once connected to power and cooling, the device is immediately ready for operation.

Special Solutions

Users can place custom orders including:

- mechanical design modifications tailored to specific requirements

- versions with separate microwave and power supply modules

Switched-mode Magnetron Power Supplies

Magnetrons are used in industrial heating and drying systems, as well as in medical and chemical equipment, plasma technologies and other advanced systems. Their operation requires dedicated power supply systems.

Magnetrons are used in industrial heating and drying systems, as well as in medical and chemical equipment, plasma technologies and other advanced systems. Their operation requires dedicated power supply systems.

The solution lies in modern impulse power supplies, where PWM technology enables precise control of magnetron output power. The principle of PWM operation is described in more detail in Tech insights.

Power Supplies Rated at 1.0–1.5 kW

The 1.0–1.5 kW power supplies are powered from a single-phase 230 VAC mains. They are intended for use with magnetrons in industrial and medical applications. Where required, they provide output voltage with a low ripple level.

The 1.0–1.5 kW power supplies are powered from a single-phase 230 VAC mains. They are intended for use with magnetrons in industrial and medical applications. Where required, they provide output voltage with a low ripple level.

Two cooling options are available. Air-cooled units feature their own ventilation system, effectively protecting internal circuits from overheating.

Water-cooled units require connection to a running water source or a closed-loop cooling system.

Microwave power setting can be configured in three ways. No regulation – the magnetron always operates at full power. 0–5 VDC analog control – the output power is proportional to the control voltage. RS-485 communication – the power is set via the Modbus communication protocol.

The control signal is connected to the interface with I/O sockets.

The magnetron and power supply are linked by high-voltage cables with appropriate connectors.

A wide range of configuration options allows the power supply to be tailored to specific operating conditions and application requirements.

Microwave Radiation Measurement

Since July 1, 2016, the Regulation of the Polish Minister of Family, Labour and Social Policy (Journal of Laws, item 950) concerning the protection of workers from electromagnetic fields has been in force. Users of microwave systems must:

- designate protective zones,

- assess hazards in the work area,

- eliminate excessive exposure to radiation.

Safety Zone Limit Values

Measurements of power density (W/m²) are the basis for assessing exposure to radiation. The following limit values serve as guidelines for users on where and how to protect workers:

- >100 W/m²: prohibited zone (no entry),

- 50–100 W/m²: working time limited to a minimum,

- 10–50 W/m²: presence limited to 8 hours per working day.

Types of Measurement Devices

Handheld Devices (portable)

They assist occupational health and safety departments in fulfilling the obligation of periodic inspections of microwave systems. Also a convenient tool for ad-hoc checks of microwave emission levels at the workplace.

- Measurement range: 0–100 W/m²,

- Quick assessment of emissions at any installation point,

- Essential for OHS reports and ad-hoc controls.

Fixed System

Used in large industrial installations. Provides continuous monitoring, constantly analyzing radiation levels at critical points such as open entrances to drying tunnels.

- Integration with measurement control units and control systems,

- Automatic process shutdown upon exceeding set thresholds,

- User-adjustable alarm thresholds.

The selection of measurement solutions requires an analysis of the installation’s specifics.