Ta strona dostępna jest również w polskiej wersji językowej

An industrial or research microwave system is based on a custom-designed waveguide system. This freedom of parameter selection allows the designer to select the microwave source and process line configuration, while the user can control the system's operating conditions.

- WR284, WR340 and WR430 standards (other standards possible),

- straight waveguides of any length (manufacturing accuracy up to ±0.1 mm),

- mounting flanges flat or with gasket,

- waveguide bend in the E-plane or H-plane (arbitrary bending angles),

- launchers matched to the magnetron type and microwave power,

- circulators and isolators (most commonly water-cooled),

- 3-stub tuners (manual or automatic),

- directional couplers for VSWR monitoring,

- waveguide short-circuit (fixed) or slider (adjustable),

- microwave vacuum windows, including versions for UHV systems.

Examples of completed orders can be found on the website Projects

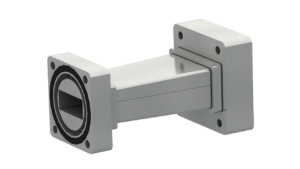

Straight Waveguide

Basic element of microwave waveguide lines. Section length ranges from 0,1 to 1,0 meter, specified when ordering. Each segment is equipped with precisely milled mounting flanges.

Basic element of microwave waveguide lines. Section length ranges from 0,1 to 1,0 meter, specified when ordering. Each segment is equipped with precisely milled mounting flanges.

Construction:

- Material: aluminum (AW-6061/6082), on request oxygen-free copper (OFC/OFHC) or stainless steel (304/316)

- Flange type: flat, with gasket, or with gasket and recess to prevent leakage

- Finish: powder coating (aluminum) / polishing (copper, steel)

Angular Waveguide

When the microwave waveguide route requires a change of direction, angular waveguides are used. Depending on the needs, the following are available:

When the microwave waveguide route requires a change of direction, angular waveguides are used. Depending on the needs, the following are available:

- H-plane bent waveguide – for horizontal direction changes (left/right)

- E-plane bent waveguide – for vertical direction changes (up/down)

Typical elements have bending angles of 30°, 45°, or 90°. It is possible to design and manufacture a waveguide with any selected bending angle. Each waveguide is characterized by low attenuation.

Construction:

- Material: aluminum (AW-6061/6082), optionally oxygen-free copper (OFC/OFHC) or stainless steel (304/316)

- Mounting flanges: flat, with gasket, or with gasket and leakage protection

- Finish: powder coating (aluminum) / polishing (copper, steel)

TAPER – Waveguide Adaptation

In microwave systems, there is often a need to change the waveguide standard. For example:

In microwave systems, there is often a need to change the waveguide standard. For example:

- In systems for generating low-pressure plasma, reducing the waveguide size increases the efficiency of plasma excitation

- In industrial production lines, it enables integration of microwave sources with different standards into existing infrastructure

A reduction in waveguide profile (tapered waveguide) or a change of standard allows to match waveguide cross-sections without impedance disruption, maintaining continuity of the waveguide path.

Specifications:

We design and manufacture waveguide transitions for any pair of standards (e.g., WR430→WR340), using aluminum AW-6082 as the base material (with the option of stainless steel 304 or 316). All parts are precisely milled, and joints are laser welded.

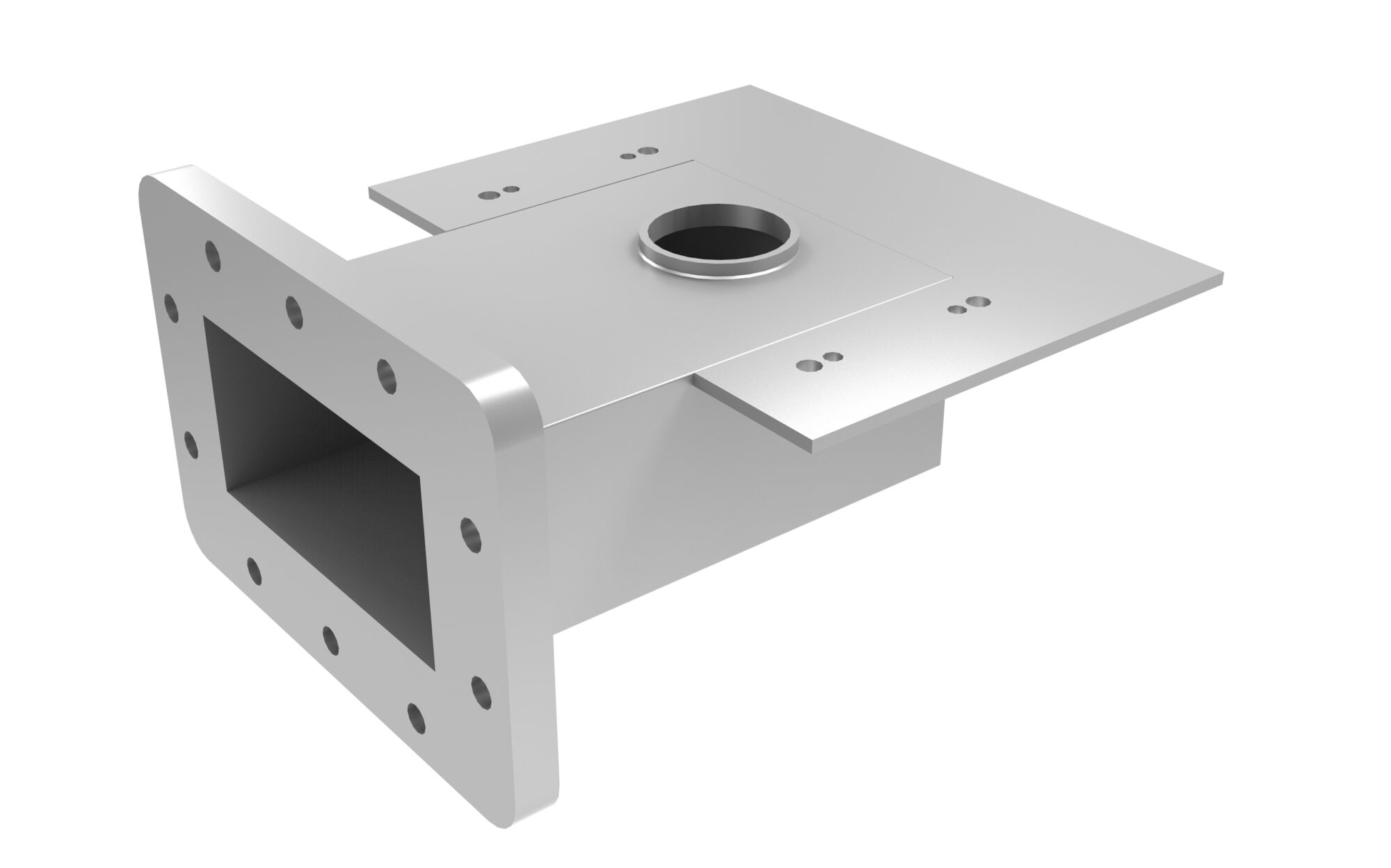

Magnetron Launcher – Specifications and Construction

The launcher connects the microwave source (magnetron) to the waveguide and efficiently transfers energy further to the process chamber.

The launcher connects the microwave source (magnetron) to the waveguide and efficiently transfers energy further to the process chamber.

MARKOM designs and supplies launchers for CW magnetrons with power ratings of up to 1500W, 3000W, and 10000W. The construction, shape, and dimensions of the launcher depend on the magnetron’s power.

Standards and Materials:

- Available waveguide versions: WR340 and WR430

- Made from materials: aluminum (6061/6082), stainless steel (304, 316), oxygen-free copper

- Mounting flange at the launcher output: compliant with the selected waveguide standard. The version with a gasket protects the inside of the waveguide from dust.

- Joining technology: laser welding (standard) or TIG welding (for increased strength requirements).

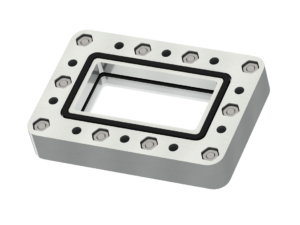

Microwave Pressure Window

This is a key component in industrial applications requiring separation of two environments differing in pressure or chemical aggressiveness. The window’s task is also to transmit microwave energy into the process chamber.

This is a key component in industrial applications requiring separation of two environments differing in pressure or chemical aggressiveness. The window’s task is also to transmit microwave energy into the process chamber.

The microwave window (dielectric barrier) is hermetic in pressure ranges from 10⁻³ mbar to 2 bar. It operates within temperatures from -30 to +150°C and can handle microwave power up to 6 kW.

Applications:

- in plasmatrons – systems generating low-pressure plasma,

- in vacuum dryers – for vacuum drying of temperature-sensitive products such as food,

- in chemical reactors – supporting production processes or research,

- in modified atmosphere chambers – ensuring controlled conditions for industrial processes.

We offer windows compatible with waveguides of WR340, WR430 standards or according to customer requirements. The primary flange materials are aluminium (6082) and stainless steel (304, 316).

The barrier is made of quartz sand. Viton (fluoroelastomer) seals ensure chemical and thermal resistance.

Coupler with VSWR Meter

VSWR (Voltage Standing Wave Ratio) is a key parameter defining the impedance matching of the waveguide path to the process chamber. Monitoring this ratio allows assessing the energy efficiency of the entire system. A coupler with VSWR measurement capability is an essential diagnostic tool in microwave systems, enabling simultaneous measurement of forward power and reflected power.

VSWR (Voltage Standing Wave Ratio) is a key parameter defining the impedance matching of the waveguide path to the process chamber. Monitoring this ratio allows assessing the energy efficiency of the entire system. A coupler with VSWR measurement capability is an essential diagnostic tool in microwave systems, enabling simultaneous measurement of forward power and reflected power.

The microwave source (usually a magnetron) generates electromagnetic waves transmitted toward the process chamber — this is called forward power. Due to imperfect impedance matching of system components, part of the microwave energy is reflected and returns to the source as reflected power. This phenomenon not only reduces process efficiency (e.g., microwave heating) but also increases the risk of magnetron failure. Regular VSWR measurement allows quick problem identification and operational parameter adjustment.

The coupler offered by MARKOM is a waveguide dual directional coupler with precision measurement probes. Key features of the proposed set:

- Reading values on an analog meter

- Power measurement range up to 3 kW with ±100 W resolution

- Waveguide type and flanges: WR340 or WR430

- Cables connecting the coupler to the meter, 1 m length