Ta strona dostępna jest również w polskiej wersji językowej

Effective microwave drying of foundations and walls does not depend on moisture level, wall thickness, or location conditions.

The recommended waterproofing of foundations is often preceded by thermal injection of the wall using microwave generators.

A microwave generator helps dry walls quickly. This is a condition for continuing many construction and renovation works without unnecessary delays.

After flooding, water supply failure, or fire brigade intervention, wet areas can be quickly dried using a microwave device.

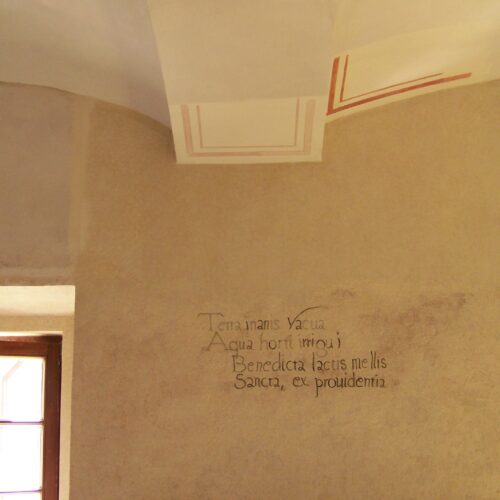

Microwave technology is used to dry residential buildings, historical structures, public facilities, and farm buildings.

Examples of completed orders can be found on the website Projects

Microwave drying technology

Many materials naturally retain water within their structure. Moisture most often fills cracks, spaces between grains, or gaps between layers of the material.

The Microwave Generator emits energy that penetrates deep into the material and is primarily absorbed by water molecules. This causes them to heat up, and indirectly warms the surrounding material.

Moisture naturally moves from warmer areas to cooler ones. The microwave energy causes the water trapped inside the material to evaporate. The resulting pressure pushes the water vapor outward through the structure.

Advantages of this method:

- Enables non-invasive drying of walls and foundations — no drilling or plaster removal required

- Effective regardless of room size, ambient temperature, or season

- Suitable for drying exposed foundations, underground passages, and freestanding structures

- Allows targeted drying — e.g., when only part of a wall is damp

- Does not leave salt residues on the surface, as minerals are not transported with the steam

- Does not negatively affect the structure of the dried material, preserving its original properties

Drying Methods

The term "wall drying" refers to several different technological approaches:

- Drying using only the Microwave Generator

This method relies solely on the use of microwave equipment, without any additional materials or chemical agents. The generator is systematically moved along the damp area. The process continues until the building structure reaches an appropriately low level of moisture. - Thermowave Method (also known as Thermo-Injection)

This is a more complex process (described on the Microwave-assisted Thermal Injection) that involves three stages:- First, a series of holes is drilled into the wall or foundation

- Next, the area is pre-dried and heated using microwave technology

- In the final stage, a hydrophobic chemical agent is injected into the prepared holes

The use of microwaves in the thermowave method is based on two key reasons. First, the hydrophobic agent can only be applied to a substrate with a sufficiently low moisture level, as specified by the product manufacturer. Second, most hydrophobic materials perform better and spread more effectively in heated masonry.

Detailed conditions for the use of thermo-injection are usually specified in the project documentation or in the recommendations of the Building Supervision Inspector.

Safety

All MARKOM microwave devices comply with harmonized standards and are CE certified.

There are several misconceptions circulating in the public domain regarding the use of microwave generators for drying building structures:

-

FALSE. Microwaves damage the wall structure

Drying is effective even when the wall temperature is below 60°C. Microwaves cause water to evaporate without the need to heat the wall to high temperatures. -

FALSE. Microwaves damage cables embedded in walls

Cable insulation is made from materials that are resistant to microwave fields. According to cable manufacturers, insulation begins to degrade only above 140°C, while the drying process does not require such high temperatures. -

FALSE. Residents must be evacuated during the drying process

The generator’s emitter precisely directs microwave energy to the selected area of the wall. Water contained in the structure absorbs over 90% of the energy, and the remaining 10% of scattered radiation is comparable to the level emitted by a household microwave oven. Additionally, the operator continuously monitors radiation levels at the work site.